SOFTWARE for Print and Mail Shops

Be the shop you’ve always dreamed of with the Print Reach Productivity Suite.

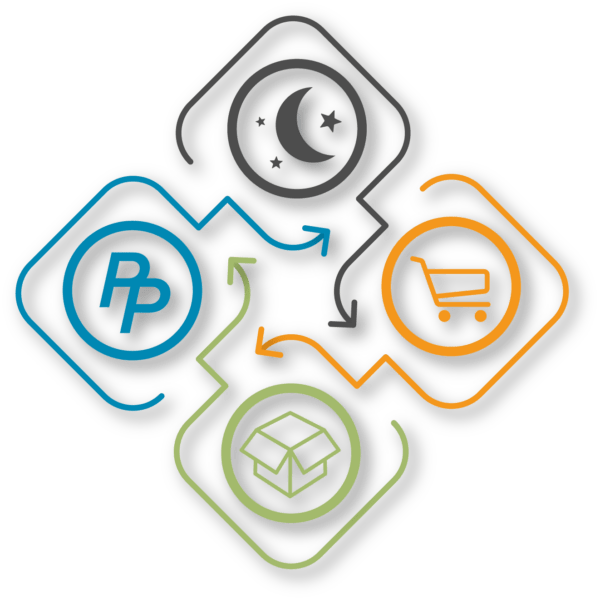

Superior Print and Mail MIS capabilities with outstanding web-to-print integration

SOFTWARE for Print and Mail Shops

Be the shop you’ve always dreamed of with the Print Reach Productivity Suite.

Superior Print and Mail MIS capabilities with outstanding web-to-print integration.

“We really pushed Print Reach to deliver on some big items that we have been desperately needing out of one system, instead of two, which is what we’ve done for the last several years. I think it goes without saying that we asked the Print Reach team to deliver on some massive reports, unlike anything they’ve built before and we are happy to say each and every one of them functions just as we hoped they would. The Print Reach team never strayed from their commitment. This platform will be one that we anchor our business on for years to come!”

Kraig Piercy

Elite Services, Inc.

Proud Member / Sponsor

Proud Member / Sponsor

Best kept secret

“I believe Printer’s Plan is one of the best kept secrets in our industry. We have been using this system for over 20 years. Printer’s Plan handles all of our needs from multiple locations to 40” print jobs.”

MALLERY MELE | MELE PRINTING

$13,000 labor savings

“We stopped having our morning production meeting recently because it was redundant and all the info is in Midnight’s scheduling module. That’s a saving of 15 minutes for 8 people which is 2 hours a day or 520 hours a year at a labor rate of at least $25/hour = $13,000 labor savings.”

John Hodgman | Direct Connection

Vision. Strategy. Relationships. Solutions.

Our Growth-and-Success Integration Partners

Want to learn the 3 critical items in your MIS and Web-to-Print search?

Enter your name and email to download the podcast.